The Best Chromate Conversion Coating Service in Dandenong South, Melbourne

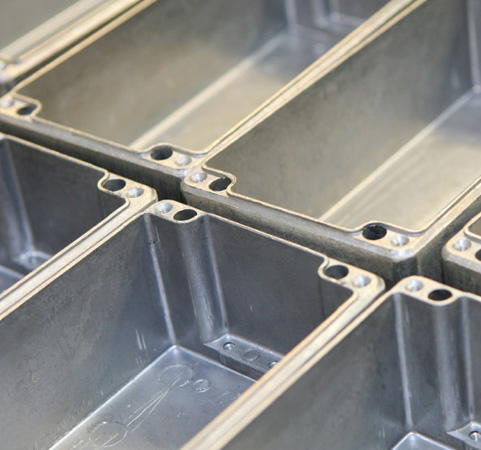

Aluminium chromate conversion coating is a type of industrial coating used to create a thick and hard finish on aluminium surfaces. This process is primarily used for the protection of aluminium in primary and secondary applications as it provides excellent corrosion resistance. It has been around since the 1950s but it has evolved significantly and it still remains one of the best ways to protect your products from damage.

Golden Powder Coating offers a wide range of chromate and other chemical conversion coating services to protect your aluminium parts from corrosion in Dandenong South, Melbourne. Whether you are looking for the best protection against salt water, acid, or alkaline environments, we can provide you with a suitable solution. Our team will work with you to ensure that you are getting exactly what you need and that you have the best results.

Benefits of Trivalent Chromate Treatment

Trivalent chromate conversion coating treatments are a type of chemical conversion coating used to passivate aluminium and aluminium alloys. Otherwise known as alodine coatings, these solutions are typically made from chromic acid. This produces a layer of aluminium and chromium oxides on the surface which becomes an effective corrosion inhibitor and primer that improves paint adherence and adhesiveness. These treatments are so popular today because of the numerous benefits they can render to any aluminium surface such as:

Increased surface hardness

This makes the material more resistant to scratches and abrasions. It also enhances moisture resistance which also protects them from chemicals and bad weather conditions. Such properties are ideal for abrasive or high-traffic environments.

Improved surface appearance

The final finish of trivalent chromate conversion coating treatment is something that always impresses. It never fails to elevate the aesthetics of the surfaces. It also allows your aluminium surface to look polished and shiny, achieving a more attractive and professional look.

Better resistance to staining

In addition to a guaranteed zero buildup on the metal parts, this solution also holds out against staining. This means that if your products get paint or oil marks on them, it will be less likely to retain that stain than an untreated surface.

Ideal for daily use items

This type of chemical conversion coating treatment is ideal for everyday items that need protection from moisture and other factors. This includes tools, appliances, vehicles, and other metal products. The treatment provides such a strong protective coating against corrosion or rusting which will last for years without needing to be reapplied or repaired in any way.

Versatility

Trivalent chromate treatment is very versatile and can be used on almost any item. It has been used for years to protect aluminium products against rust, discolouration, and corrosion. Plus, it has unique “self-healing” properties that allow your tools to recover from light scratches in no time.

Cost-effective

This type of treatment is typically less expensive than other options. It takes less time to apply than other methods, such as painting or waxing and is usually much more effective as well.

Primary Attributes of an Alodine Finish

Alodine conversion coating provides aluminium surfaces with a durable and transparent finish. It is usually applied by dipping the metal in an alodine solution and then drying it. The main attribute of an alodine finish is that it protects the metal from corrosion and oxidation. Additionally, the treatment also provides the following attributes:

Highly resistant

Alodine coating on aluminium improves its resistance to the various environmental conditions like saltwater and humidity. This makes it ideal for aerospace and maritime application. It is also used in the military as they operate in harsh environments. Alodine-coated aluminium is also used in the electrical industry due to its unmatched resistance to corrosion which effectively protects wire housings and panels.

Reduces electrical conductivity losses

Due to its excellent corrosion resistance properties, alodine conversion coating can significantly reduce electrical conductivity losses significantly. This means that less energy will be required to run your machine or device, saving you money and extending the life of your equipment.

Provides a smooth, uniform appearance

You do not have to worry about uneven colouration or texture with alodine conversion treatment. It will be evenly applied to the surface without any bumps or stains.

Improved durability and easier maintenance

Alodine finish, also known as chem film aluminium, creates a smooth surface that is resistant to corrosion. It can be cleaned with much less effort than other options. This saves time and money while increasing the durability and lifespan of your parts.

Affordable Aluminium Chromate Conversion Coating in Dandenong South

Golden Powder Coating is a chemical conversion coating service provider for both residential and industrial applications in the South East Suburbs of Melbourne. We specialise in providing high-quality and budget-friendly coatings for your parts. Our team of expert technicians has been working with chromates for over 15 years. So we know what it takes to deliver the best results possible.

Given our experience in the industry, we are confident that our expertise will help you meet all of your aluminium coating needs. Choose our services for

Top-quality results

We are a fully insured and certified company. This guarantees that we will always meet the highest standards of quality in our business practices. Our commitment to providing the best services and products is unmatched. That is why we deliver the best results and meet your client’s expectations on every project.

Excellent customer care

We have a customer care team that provides the best support. Additionally, our chemical conversion coating specialists are always available to advise on your project. This ensures that everything runs smoothly from start to finish.

Detailed quotes and contract

We want to ensure you get exactly what you want and are aware of all costs involved before we start work. This approach guarantees 100% customer satisfaction. It also facilitates transparency in our business dealings.

Get Long-lasting Chemical Conversion Coating Treatment Today

The best way to ace your aluminium coating project is with the help of real professionals. And by that, we mean the experts at Golden Powder Coating. We have been around for over a decade, and are proud to say that we have never let a customer down. If you need help with your next project, feel free to call us on (03) 9706 8593. You may also write to us at info@goldenpowdercoating.com for more details.

FAQs

To apply alodine, you’ll need to let it sit on the aluminium for at least 2-6 minutes. This time estimate will also depend on the activity and surface temperature. The longer the alodine sits on the metal, the more time it has to soak into the pores and bond. But remember not to go overboard as it may not result in the outcome you desire.

Passivating is a standard step in electroplating. The passivate, or chromate solution, is used to seal the zinc plating after the plating of the tank. It enhances corrosion resistance and can be used to add colours.